Who is CDS AQS

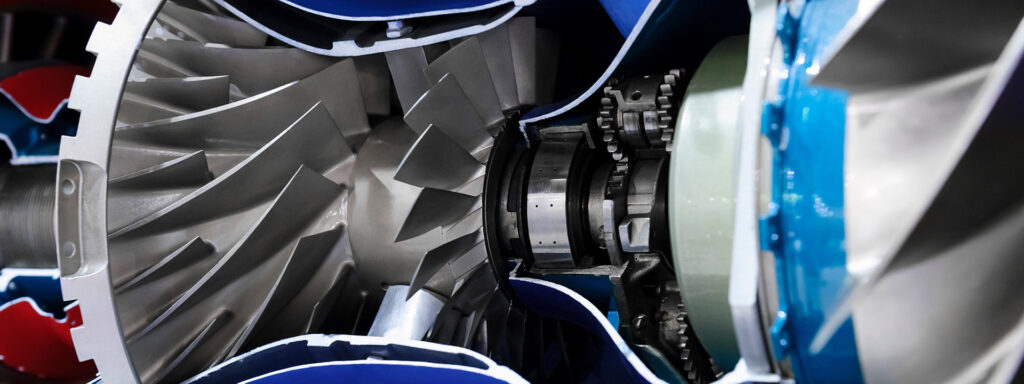

We have over 100 years of accumulative work experience we can bring to bear on improving your Quality Management System.

Our team of certified auditors in Dallas have worked at large commercial and defense Original Equipment Manufacturers, prime sub-tier suppliers, 2nd / 3rd tier suppliers, and NADCAP-certified suppliers so we understand the demands placed on the entire supply chain. We have helped develop the quality requirements which are flowed to the supply base as well as dealt with applying those same requirements throughout our quality management systems. We draw on years of program quality experience which can be directly applied to your company operations. Several of our team members have developed and deployed advanced quality solutions which positioned OEMs to meet and exceed their affordability targets and process capabilities. We have redefined First Article Inspection processes and contributed to aerospace standards development and guidance material. Many of our team members in Dallas, Houston, Michigan and Phoenix have years of adult teaching experience which can be put into motion to ensure the solutions we collectively arrive at are clearly communicated, understood, and put into practice within your organization.

Established

Areas of Expertise

- Sub-tier control (including maturity assessments and predictive surveillance)

- Variation Management (including Key Characteristics)

- Process Control documentation and implementation

- Process Failure Modes and Effects Analysis

- Advanced Product Quality Planning (APQP)

- Measurement System Analysis (MSA)

- First Article Inspection / Production Process Verification / Production Part Approval Process (PPAP)

- Quality Management System development

- Risk analysis and mitigation

- Energy Management System implementation and sustainment

- Petroleum and Natural Gas Manufacturing and Service Supply Quality Management System implementation and sustainment

- Lean Manufacturing

- Training development and facilitation including classes in Blueprint reading, Geometric Dimensioning and Tolerancing (GD&T)